Drying filament is one of the most important things you should consider when doing 3D printing projects. Be aware that all FDM 3D printing filaments absorb moisture (hygroscopic).

Moisture is one of our greatest enemies. But don’t worry, we are here to provide the best solutions to fight this monster.

Before we dive into how to avoid moisture, we want to explain why it is imperative to dry your filament before using it.

The Importance of Drying Your Filament

Polymers can be seriously affected by the introduction of water molecules. When you have a wet filament, then your projects can fail or even break your printer.

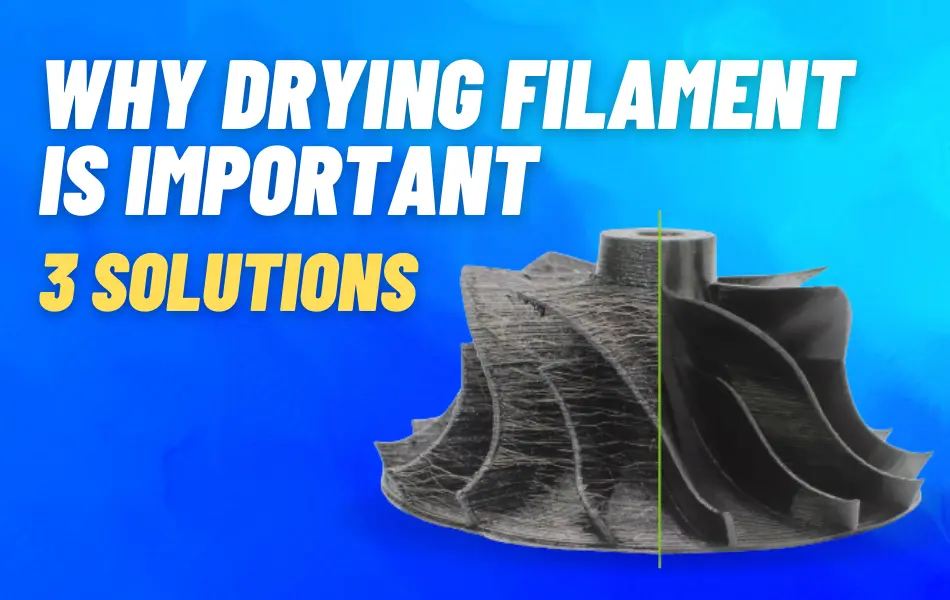

It can be quite difficult to spot if your filament is “wet” by just looking at it. However, you will be able to notice when printing.

If your filament spools are “wet”, then you will experience things like:

- Uneven extrusion lines

- Stringing, oozing, or blobbing

- Textured surfaces on your projects

- Lack of layer adhesion

- Reduced sizing on prints

- Popping sounds while printing.

- Clogged Nozzle (unable to extrude)

After testing its integrity, drying your filament at the right temperature will grant a successful print.

Anticipate the Moisture Problem

Before we dive into drying filament techniques, you need to have storage solutions to keep it dry once you purchased and for leftovers.

Thus, having these storage methods will prevent the bad experience of starting your project with a wet filament.

We recommend you follow these 7 solutions for 3D printer filament storage.

How to Dry Your Filament

Food Dehydrator

These can work as filament dehydrators since they are designed to remove excess moisture by slowly providing low heat. In addition, it allows the items placed in it to last longer.

Using a dehydrator is quite practical to use. Just place the 3D filament inside, set the temperature, and leave your spool inside to dry.

Temperature to dry filament using a Food Dehydrator

| Material | Temperature |

| PLA | 40°C-50°C |

| ABS | 80°C (or the highest available temperature) |

| Nylon | 80°C (or the highest available temperature) |

Cooking Oven

Like any other cooking preparation, before you place the food inside the oven, this one needs to be preheated. This will grant that when you place the filament, it will dry at the correct temperature.

We highly recommend placing a thermometer inside the oven to validate that the temperature shown on the screen is the same as the one inside.

Temperature to dry filament using a Cooking Oven

| Material | Temperature | Time in Oven |

| PC | 80°C-90°C | 7-10 hours |

| ASA | 80°C-85°C | 4-6 hours |

| Nylon | 75°C-90°C | 4-6 hours |

| ABS | 65°C-75°C | 4-6 hours |

| PETG | 60°C-65°C | 4-6 hours |

| PLA | 40°C-50°C | 4-6 hours |

| TPU | 40°C-45°C | 4-5 hours |

Filament Dryers

Using a dryer made for filaments can be more expensive, but removes the guesswork and lets you focus on your printings. These filament dryers work under temperature-control hot air.

Furthermore, this air gets pumped into the chamber to remove moisture, which passes through a release vent.

To prevent filament warping, the spool can rotate for even heating. Also, these filament dryers can also work as storage solutions for leftovers.